Keycap Material: ABS, PBT, PVC, POM

Keyboard's key's keycap material use many variety of plastics. The plastics usually have chemistry names, e.g. ABS, PBT, PVC, POM.

Each type has special properties, such as hardness, feel to touch, sensitivity to heat, decoloration, melting point, shrinkage, and manufacturing cost, and how easy is it to put key labels on the plastic with various Key Label Printing Tech.

What is ABS keycap?

Most cheap keyboard's keycaps are made of ABS plastic. ABS is short for Acrylonitrile Butadiene Styrene.

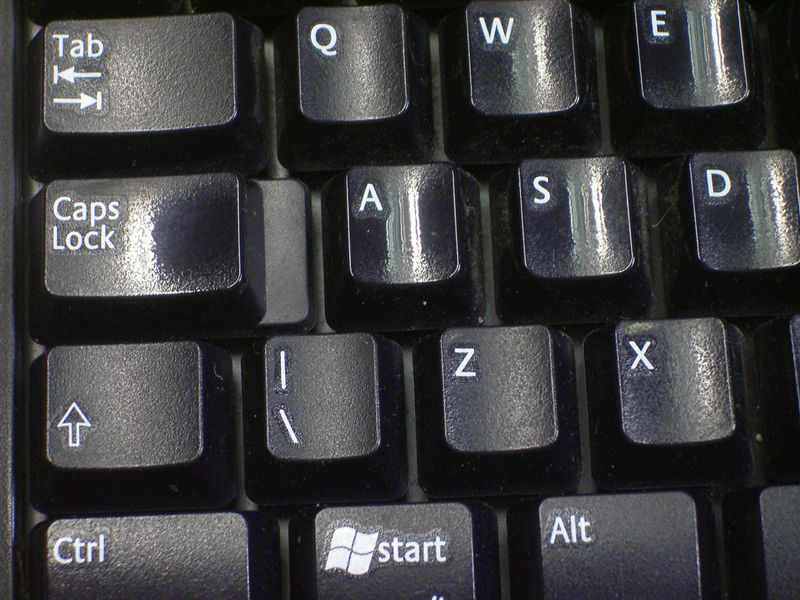

ABS keycap is prone to wear scar. After a year of use, the surface of the keys become shiny, also there's a slight dent by wear

After 3 years of heavy typing, the little tactile bump on the key J has completely worn off in one of my keyboard.

The choice of keycap plastic is tied to choices for the method of printing key labels.

Even though ABS keycap has flaws, but it has a advantage, for creating the best key label via double-shot molding.

ABS keys is the preferred plastic to double-shot molding. That is because most other plastics shrink too much in the molding process. Legends on ABS keys can also be pad-printed, laser-etched (burned) or laser-engraved (with or without infill). Because of the low shrinkage, some keyboards have space bars made of ABS even if other keys are made of PBT or POM. [deskthority.net/wiki]

Note, the “double-shot molding” is one of the best tech for key label, because it mean the label will never wear off. 〔see Key Label Printing Tech〕

What is PBT Keycap?

- PBT stands for polybutylene terephthalate. it's a type of plastic.

- PBT keycap is hard, and is typically used in more expensive keyboards.

- PBT keycap does not yellow over prolonged sunshine.

- PBT keycaps are often preferred by keyboard experts.

key labels on PBT keycaps may be laser-etched, dye-sublimated, rarely double shot moulded, because of shrinkage during demoulding. PBT is also rarely used for the largest key, the space bar.

Here is examples of keyboard with PBT keycaps.

What is PVC Keycap?

PVC (short for “polyvinyl chloride”) is a relatively hard, middle-of-the-road plastic used in keycaps. Production of PVC is somewhat environmentally unfriendly and it is therefore not manufactured in some parts of the world.

It is probably the second most common keycap material, after ABS, widely used by Logitech, Dell, HP, and other mass market brands. PVC has average hardness and friction, but is sensitive to high heat, which will warp it.

PVC legends are often pad printed or stickers, due to its wide use in the mass market, though laser printing with infill can also be observed.

[2017-02-21, from https://deskthority.net/wiki/Keycap_material ]

POM Keycap

POM (short for “Polyoxymethylene”) is a thermoplastic. It is sometimes called “Acetal” or “Polyacetal”. POM is hard and durable but has low friction, being slippery to the touch. It is more dense than PBT and ABS, and keycaps made of POM tend to have a more muted downstroke.

Legends on POM keys are usually laser-engraved, with or without infill.

Keycaps of POM can not be found on many keyboards. Cherry uses it currently for black keys on its contemporary keyboards in the G80 and G81 series.

Sliders in mechanical key switches are often made of POM. The natural unpigmented appearance of POM is translucent white, which can be seen in the slider of Cherry MX Clear. There are technically two variations of POM: homopolymer and copolymer. The homopolymer is somewhat stiffer and stronger but the copolymer is more dimensionally stable and has less friction. The chemical giant DuPont has the popular brand "Delrin" (not to be confused with the keycap manufacturer "Devlin") for the homopolymer form. It is suitable for machining and laser-cutting and has been been used for plates in some custom keyboards.

2023-01-28 from https://deskthority.net/wiki/Keycap_material

POM is chemically and mechanically resistant. It doesn't yellow easily, and unlike ABS doesn't shine easily. Of all keycap materials POM and PBT have the best type feel. If you like it rough PBT. If you like it smooth POM.

One downside to POM is the difficulty and cost to make. It has a much higher shrinkage rate than ABS and PBT, so it is much more demanding on the mold and the injection molding process.

After the 90s POM lost favor as all the big companies switch over to much cheaper PVC and ABS caps. These days hardly anyone makes POM caps. PBT had a revival because it can be made with ABS mold due to similar shrinkage rate. But for POM you need a dedicated mold.

2023-01-28 from Stephen Chen, creator of Glove80 Keyboard

example, POM keycap is used by

Reference

[2017-02-21, from https://deskthority.net/wiki/Keycap_material ]

worn keyboards

worn keyboards Kinesis 360

Kinesis 360 UHK 60

UHK 60 Glove80 Keyboard

Glove80 Keyboard Keycaps: ABS, PBT

Keycaps: ABS, PBT Key Label Tech

Key Label Tech Cute Keycaps

Cute Keycaps